Don't miss our holiday offer - up to 30% OFF!

rom CAD to First Shot: The10-Day Reality Check

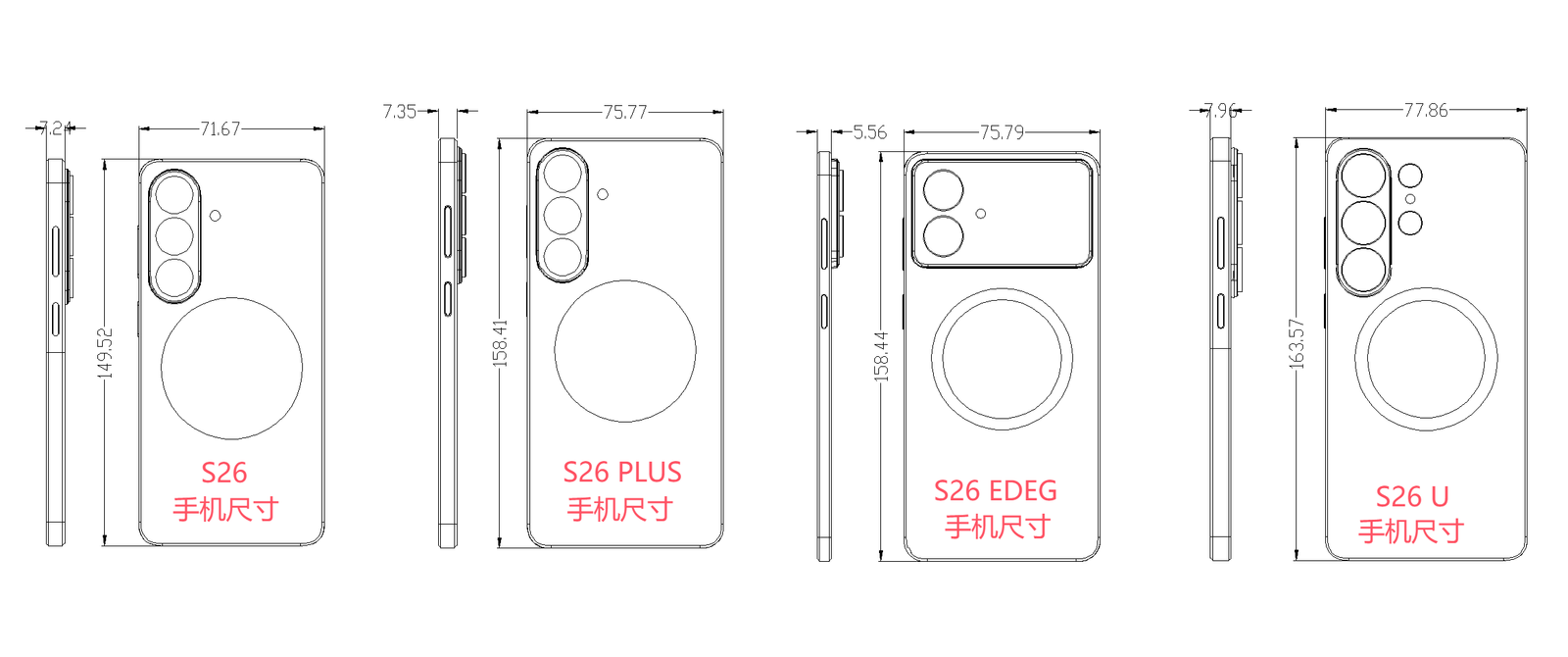

When the S26 series dimensional drawings landed on our desk, they looked like any other PDF: clean lines, precise numbers, variants for Plus, Edge, and Ultra models. The design phase wasn’t about inspiration—it was about hunting for landmines.

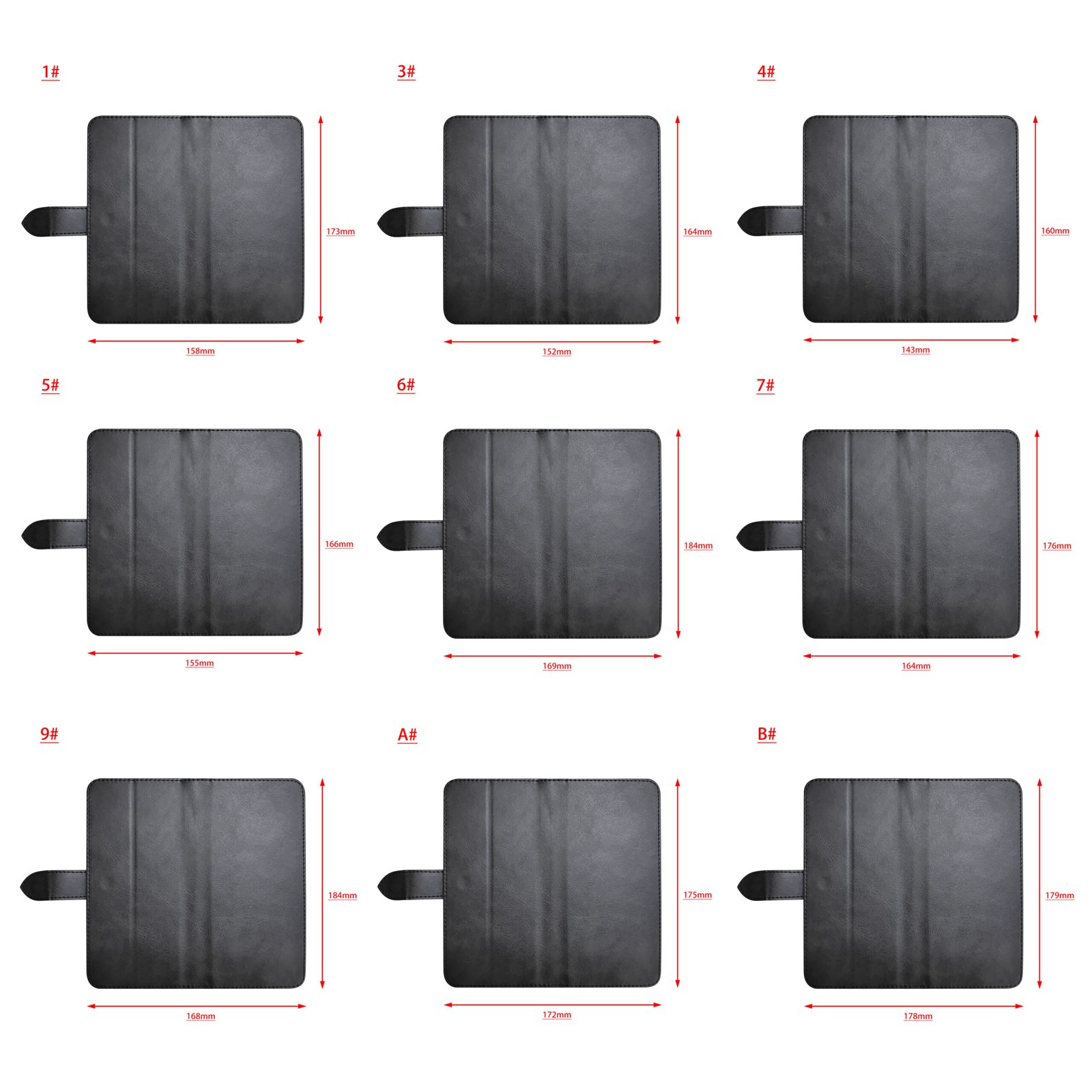

Spec sheet for leather inserts. The 2mm differences between #3, #5, and #7 variants dictated five separate cavity adjustments—what looked like minor variations required entirely different insert molds.

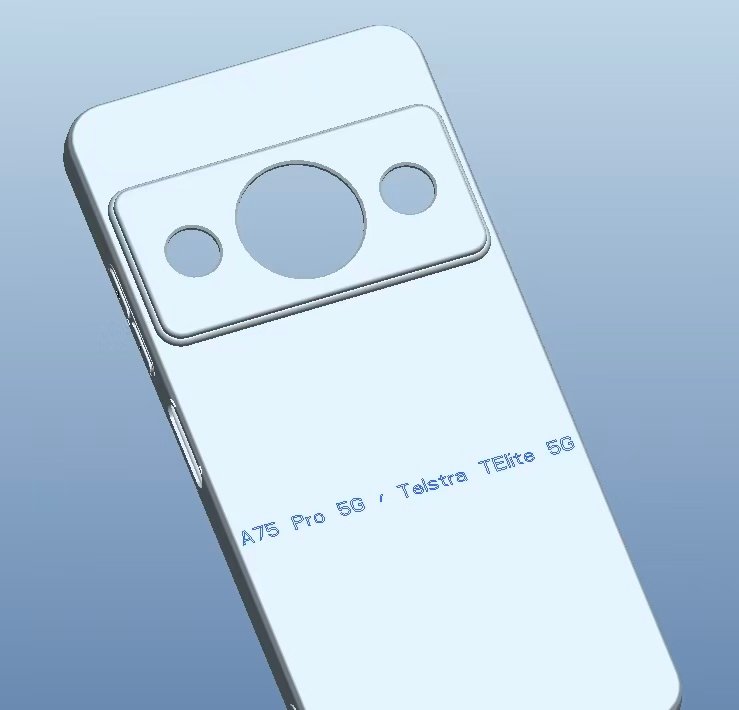

Our team spent three days just measuring. The camera bezel: 7.35mm high. The chassis width: 75.77mm. The leather insert for the back panel had five size variants—#3, #5, #7, #9, #A—each differing by 2mm in length and 3-5mm in width (see the spec sheet). We argued over 0.1mm tolerances. The radius on the bottom corners looked fine on screen, but we knew from the A75 Pro project that anything under 3mm would cause TPU stress whitening.

Phone dimension chart. Numbers like 7.35mm and 75.77mm drove our tooling decisions, but the real engineering happened when we discovered those measurements shifted by 0.2mm after the phone’s assembly process.

The mold order went out: $8,400 for hardened steel, three-week lead time. When it arrived, the first shot seemed perfect—until we clipped it onto an actual S26. The volume button hole was offset by 0.3mm. The leather recess from the drawing looked right, but the real veneer refused to sit flat. The problem? The drawing showed the phone’s ideal state, not the microscopic seam where the glass met the frame.

The breakthrough wasn’t dramatic. On day10, after scrapping 400 units, we added three venting channels to prevent flow marks near the charging port. The leather finally seated within the 0.2mm tolerance. The buttons clicked correctly. We signed off with a 12-page mold modification log, not champagne.

That’s the process. Not elegant, just systematic elimination of every way plastic can disappoint you. The final case is simply the version where we ran out of problems to solve.

10-Day Reality: From Design to Mold

A 10-day, unglamorous journey from design to mold—success comes from systematically eliminating micro-defects on the shop floor, not from CAD magic.